ENVIRONMENTAL ISSUES

Environmental issues are one of the largest challenges that face the fisheries sector, and considerable efforts have been spent on digitally mapping the environmental impact of the company and reducing such negative impact. These efforts have, in recent years, had the effect of annual reductions in the emission of greenhouse gases. The emission of greenhouse gases from HB Grandi fell by 9.8% in 2017 as compared with 2016, even though the total catch increased during the same period from 141,855 tonnes to 152,868 tonnes.

The reason can be traced to a number of factors and events, including the fact that the year began with the fishermen’s strike that lasted to the middle of February. Fewer and more efficient vessels now utilise fuel better than before; with the renewal of the fleet, HB Grandi has completely discontinued the use of heavy fuel oil and at the same time, increased the use of more eco-friendly energy sources such as connecting vessels to land-based electricity when they dock. The same applies to the company’s fish meal plants which were previously run on fossil fuels but are now for the most part run on electricity. This is also true of other processing plants on land, which have long been run on electricity and have been developed to fully utilise all raw materials, minimise waste and create increased value at the same time.

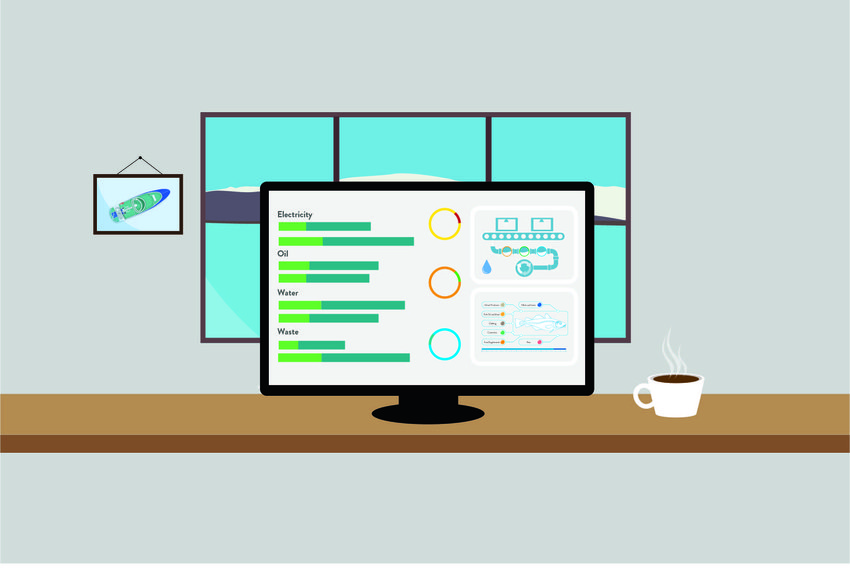

The environmental dashboard of HB Grandi digitally shows all the main aspects of the company’s environmental issues, making it possible to support its goal for an improved emission footprint and the measures taken from time to time. In order to ensure the reliability and frequency of the environmental results of HB Grandi, the collection of environmental information is based on automated data collection from the main operations and suppliers of the company. This makes it possible to monitor the benefits of individual measures taken in environmental matters.